Flexi Narrow Aisle design, manufacture & market the award-winning Flexi Digital articulated warehouse trucks

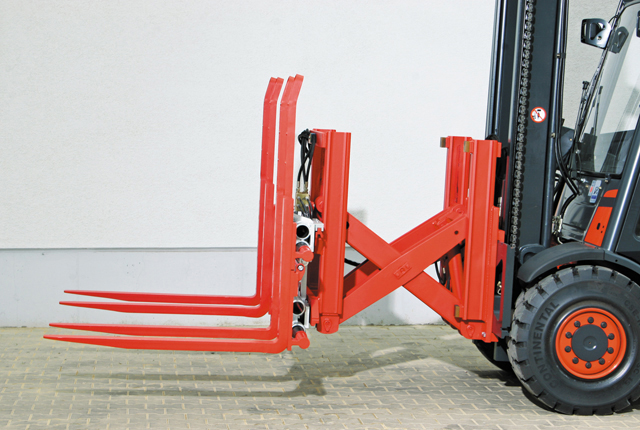

Double Pallet Handler Forklift Attachment

A double forklift lets you move more loads faster, minimize damage and stay competitive with the Cascade single-double pallet handler. Achieve the productivity gains of double unit load handling without sacrificing the ability to handle single pallets. Pallet industry recyclers will further classify Grade B pallets into subcategories according to the number of repair patches the pallets have per forklift cavity and the types of repairs completed. Repairs made with metal plates and fasteners tend to be more secure and streamlined. Dec 09, 2020 Pallet industry recyclers will further classify Grade B pallets into subcategories according to the number of repair patches the pallets have per forklift cavity and the types of repairs completed. Repairs made with metal plates and fasteners tend to be more secure and streamlined. A wide variety of double pallet forklift options are available to you, such as 1 year. You can also choose from new double pallet forklift, as well as from none, south africa, and egypt double pallet forklift, and whether double pallet forklift is hotels, or building material shops. There are 2,441 suppliers who sells double pallet forklift on Alibaba.com, mainly located in Asia. Forklifts For Sale: 5674 Forklifts - Find Forklifts on Equipment Trader. Forklifts For Sale: 5674 Forklifts - Find Forklifts on Equipment Trader. 2012 Toyota Industrial Equipment 8BDRU15 Double Reach Miller Equipment Co. 2016 Toyota Industrial Equipment 8FBCHU25 Miller Equipment Co.

Single Double Forklift Attachment

The Digital Range of articulated fork trucks has been developed specifically to improve storage and handling

- Next-generation Digital power brushless technology

- Independent power steering and lift motor digital control technology

- Up to 230° of Articulation Safe independent digital power steering, no kickback

- Easy to drive, smooth control at all times

- Stacking aisles down to 1.6 metres

- Lift heights up to 14 metres

- Load capacity 1.5, 1.7, 2.0 & 2.5 tonnes

- Unique safe HiViS operators guard

- Elastic rubber tyres all round for use on all floor surfaces

Our Flexi digital trucks are improving warehouse efficiency & profitability

The Flexi range of articulated trucks has been developed specifically to improve storage handling and aid customer order assembly efficiency in manufacturing, logistics and eFulfillment industries.

Flexi provides a more space-efficient storage solution by eliminating dead aisle space required by counterbalance or reach forklifts. Depending on the building, our product can increase usable storage space between 25% and 50% and eliminate double handling operations. This makes customer warehouses more efficient and reduces the cost of pallet storage significantly.

The Flexi Truck package does not just include the most comprehensive range of articulated VNA warehouse truck solutions. Our customers have available a full range of project planning services, free site surveys, warehouse layout planning and design services. We provide a range of easy and comprehensive operator training courses, and we offer our authorised distributors Flexi technical training including SE installation and commissioning services.

Our aftersales support is excellent with parts and service cover through our distributor network in over 65 countries globally. Our global authorised distributor network is committed to providing first-class spare parts warranty and service support to Flexi customer across the global demanding intralogistics sector.

Our Flexi Authorised Distributors globally stock Flexi spare parts and service consumables to ensure long term high Flexi uptime. Their service standards and response are the best in our industry.

The Flexi Digital range has a long-standing reputation for reliability and low maintenance costs. All Flexi Digital trucks are built with the same high-quality drive and hydraulic components which are sourced from tier one suppliers and then fitted into every Flexi truck built. The Flexi range is designed with a large proportion of common components and parts. This means the holding and provision of spare parts is made much easier for our central parts operation and our global authorised distributors.

This policy of components standardisation and high-quality suppliers allows the Flexi range of articulated warehouse reach trucks to be delivered with a market-leading Five Year /5000-hour parts warranty (conditions apply), to give complete peace of mind.

To find your nearest distributor/service provider, please contact our customer team on 0121 557 6242

Sensitive handling

Agility combined with high drive capacity

The electric double stackers D12 – D14 are very flexible when it comes to storing and removing goods, for longer transport distances with two pallets or for quick order picking processes. A high working speed is also guaranteed through the Linde OptiLift controls. It enables precise lifting and lowering of the load. At the same time, the operator maneuvers the truck with no effort using the electric steering unit and adjustable steering resistance. The truck is also very agile with its compact chassis. Thanks to the high performance 3 kW three-phase motor, the double stacker can reach a maximum speed of six kilometers per hour. Its lifting capacity is 1200 to 1400 kg.

The truck automatically reduces its speed when cornering. This protects the operator and the load from tipping. If the operator releases the driving switch, the double-decker forklift brakes automatically. A load-dependent electro hydraulic brake is immediately triggered when the operator hits the emergency stop button. A good view of the load also contributes to increased safety. The chassis is rounded, reducing the risk of injury. The design of the tiller head also reduces the risk of crushing. Items of clothing cannot become caught.

- Speed reduction when driving through curves

- Automatic braking when the drive switch is released

- Load-dependent brake when hitting the emergency stop

- Optimal visibility through the mast

- Rounded chassis shape

- Safe tiller head design

The ergonomic operation of the tiller and the spaciously designed compartments for clipboards, data terminals or laser scanners provide for a user-friendly workplace. The double stacker is also easy to drive with the electrical steering unit and adjustable steering resistance. The strain on the operator is reduced, even during maximum duty.

- Ergonomic operation

- Spaciously designed storage compartments

- Electrical steering unit for effortless handling

Using the electrical power steering including adjustable steering resistance, operators can easily control the truck and maneuver effortlessly. The Linde OptiLift control on the tiller provides for precise load handling. The operator controls all driving and lifting functions intuitively. The high performance 3 kW three-phase motor achieves a maximum speed of 6 km per hour even with a full load. The speed adjusts to the steering movements.

- Safe and precise load handling with Linde OptiLift

- Power steering with adjustable steering resistance

- Intuitive operation of all driving and lifting functions

- Powerful 3 kW three-phase motor

A multi-function display provides information to the operator about the status of the truck. The service technicians then profit during servicing: After connecting the notebook to the CAN bus connection, they will immediately see all of the relevant data and can assess it rapidly. Service components are also easily accessible. Moreover, the three-phase motors don't require servicing. This also increases the availability of the pallet stackers.

- Multi-functional display for all relevant truck information

- CAN bus connection for rapid truck diagnosis

- Easy access to the relevant device components

- Maintenance-free motor

| Model | Load capacity/Load | Lift | Travel speed, with/without load | Turning radius | Battery voltage/rated capacity (5h) |

|---|---|---|---|---|---|

| D12 | 1.2 / (2.0) (t) | 1924 (mm) | 6 / 6 km/h | 1860 (mm) | 24 / 375 [205/410] (V)/(Ah) o. kWh |

| D12 HP | 1.2 / (2.0) (t) | 1574 (mm) | 6 / 6 km/h | 1860 (mm) | 24 / 375 [205/410] (V)/(Ah) o. kWh |

| D14 | 1.4 / (2.0) (t) | 1924 (mm) | 6 / 6 km/h | 1860 (mm) | 24 / 375 [205/410] (V)/(Ah) o. kWh |

Optional Equipment

Compartments for data terminal or bar code reader

The wide, deep compartments are perfect for data terminal, the bar code reader or even film rolls, work gloves and writing implements.

Cold store design to -35°C

The cold store version guarantees full availability and performance of the truck up to minus 35° Celsius.

Load backrest

The load backrest ensures that loads cannot slide backward when the load carrier is raised.

Mobile or fixed battery holder for lateral battery replacement

The rolling battery function in combination with the removable rack is ideal for applications requiring frequent battery changes.

Lateral battery replacement

The lateral battery replacement with roller bearings enables quick changes for use in multiple shifts.

Soft Landing function for the fork carriage

The forks are braked before landing with the “Soft Landing” function so that the loaded goods sink softly to the floor.

D12/14, D12 HP